The home of Specialist Crafts ![]()

Checkout using your account

Checkout as a new customer

Creating an account has many benefits:

- See order and shipping status

- Track order history

- Check out faster

Beginner’s Guide to Pottery: Essential Tips and Techniques

Discover the timeless art of pottery with this beginner’s guide which will introduce you to essential techniques, tools and tips to help you start your pottery journey with confidence.

Whether you’re shaping your first bowl or experimenting with decorative designs, this guide will inspire your creativity and set you on a path to mastering the craft, one piece at a time.

Step by step - Let's Create

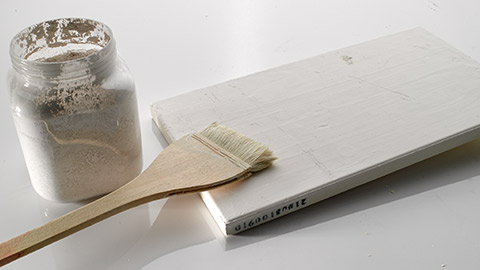

Buff school clay is a great all-rounder, and is a fantastic starting point for most ceramic projects. When fired, it will turn a light buff colour which is easily glazed. Using a cheese wire, cut a chunk of clay 9 by 18 by 2cm.

Roll the clay slab flat using rolling guides to ensure a uniform thickness. Take care when rolling out and turning the clay, and avoid lifting the clay at the edges to prevent curling. To stop the clay from sticking to the table top, roll it out on top of a cloth.

With a pottery knife, trim your clay slab to a 15cm-by-15cm square, using the rolling guides as a straight edge. Now add texture to your tile! Marks can be made in the clay using a variety of tools, including wooden stamps.

Once the tile is finished, it needs to be left to dry thoroughly. This could take several days. When the clay is completely dried out, it will turn a light grey colour and should feel warm to the touch. Once your tiles are all dry, they can be packed into the kiln for firing.

Place the tiles in the kiln, ensuring they are not touching each other, and there is sufficient room between each of them to allow the air to circulate. When you have packed your kiln, it’s time to set the controller for a ‘bisque’ or ‘biscuit’ firing. The settings we have listed are for a 3-stage kiln controller. If you have a 2-stage kiln controller, give us a call and we can advise on which settings to use.

For bisque firing:

• Remove the top bung from the kiln.

• Set the first ramp* for 50°C, with a target temperature of 80°C. Dwell* for 1 hour.

• Set the second ramp for 100°C, with a target temperature of 600°C. Dwell for 10 minutes.

• Replace the bung in the kiln when the temperature reaches 600C, approximately 7 hours after the firing program has begun.

• Set the third ramp for 200°C, with a target temperature of 1120°C. Dwell for 10 minutes

This firing takes approximately 11 hours. Once the kiln has cooled to below 40°C, the kiln can be opened and the ceramic tiles can be removed. The tiles can now be glazed with Brush-on Earthenware Glaze. Stir the pot thoroughly, and brush on evenly. Three coats of glaze should be applied to achieve an even colour. Wipe off any glaze residue on the bottom and a little up the edge of the tiles using a damp sponge, as this will cause the tiles to stick to the kiln shelf.

New kiln shelves need coating in 3 layers of kiln wash to prevent any glaze sticking, letting each coat dry between layers. For old kiln shelves, scrape off kiln wash once it no longer looks smooth, and reapply as above. Pack your kiln as before.

For earthenware glazing:

• Remove the top bung from the kiln

• Set the first ramp for 100°C, with a target temperature of 600°C. Dwell for 10 minutes.

• Replace the bung in the kiln when the temperature reaches 600C, approximately 6 hours after the firing program has begun.

• Set the second ramp for 250°C, with a target temperature of 1040°C.

• Dwell for 10 minutes

This firing takes approximately 8 hours.

Once the kiln has cooled to below 40C, the kiln can be opened and the ceramic tiles can be removed.

*Ramp: temperature rise, in °C, per hour.

**Dwell: time held at set temperature